Efficient manufacturing requires a commitment to streamlining every aspect of the manufacturing process. Efficient manufacturing requires a commitment to streamlining every aspect of the manufacturing process. By controlling material storage and distribution, manufacturers can ensure fast, accurate product assembly.

What are the benefits of kitting software? Containerization and kitting software gives manufacturers the ability to consolidate item transactions to a single scan. Containerization can reduce the number of movements and required for inventory. At the same time, it allows for kitting together components and assemblies required on the shop floor.

Taken together, containerization and kitting can help manufacturers avoid errors, streamline operations, and efficiently keep production moving. Here are four benefits of containerization and kitting software:

1. Part, product, and container relationships

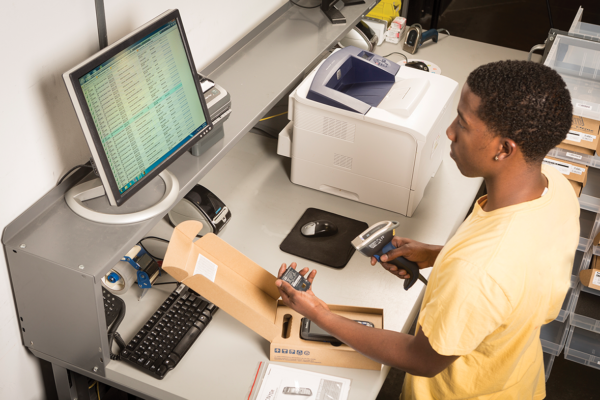

Containerization and kitting enable related items can be conveniently grouped and packaged together. This can be far more efficient than supplying items individually. Through a single scan, employees can quickly see which items are in a container or pallet, providing workflow visibility.

2. Improved efficiency and accuracy

By grouping parts together during the manufacturing process, assemblers won’t need to spend time seeking parts on their own. This ensures that the right parts are always available, and can also limit the number or type of parts employees are able to access. This reduces the potential for errors throughout the manufacturing environment.